Description

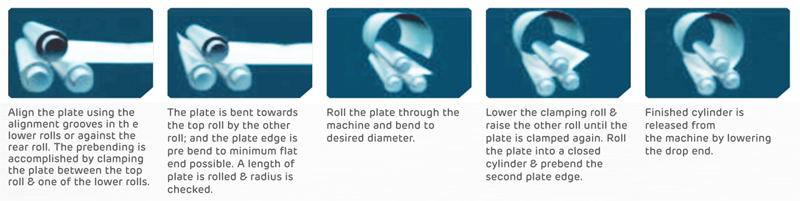

The PBM DP arrangement 3 ROLL PYRAMID TYPE HYDRO-MECHANICAL PLATE BENDING are planned with twofold side pre-squeezing course of action. The one of a kind outline allows the pre-squeezing of employment by both base rolls; subsequently the occupation is finished in single operation. This component makes the machine more gainful and reasonable for taking care of overwhelming employments. The top roller is settled and pre-pinching by both base rolls are through pressure driven barrels.

The job is bolstered from one end to complete pre-squeezing and whole shell is moved to wanted curve span. Flip side pre-squeezing is done by second base move to finish the shell. The complete shell is set up in single operation

Features

- 3 Roll PYRAMID Type outline with twofold pre-squeezing game plan

- Top roll is repaired and base moves and down.

- Base moves up-down through water powered chambers.

- Two base rolls are force driven via planetary apparatus box with electric or water powered engine.

- Twisting rolls are made of combination steel.

- Dropper end assurance by pressure driven barrels.

- Over-burden prevention

- Low part, smooth operation and less power utilization because of water powered framework works at lower weight in littler thickness.

- Assembled – in cone bowing connection.

- Global quality Hydraulic and Electrical.

Accessories

- Main drive motor

- Remote electrical panel console with push buttons

- Manual Centralized lubrication System

- Planetary gearbox attached with electric or hydraulic motor

- Digital readout for both bottom Roll position.

- Hardened & Grounded Rolls

- Automatic Lubrication system

- Motorized Drive on end dropper.

- Extended shaft with profile bending rolls.

- Conical bending arrangement.

- Material feed table.

- Digital Readouts.

- NC controls.

Specifications

| Model | Pre-Bending Capacity | Bending Capacity | Bending Length | Top-Roll Diameter | Side-Roll Diameter | Min o in Pre-Bendingr | Min o in Bending | Lenght | Width | Height | Width | Motor Power |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DP-PBM 815 | 6 | 8 | 1500 | 185 | 165 | 278 | 555 | 3300 | 1500 | 1200 | 3000 | 5.5 |

| DP-PBM 1015 | 8 | 10 | 1500 | 205 | 185 | 308 | 615 | 3700 | 1500 | 1200 | 3500 | 7.5 |

| DP-PBM 1315 | 10 | 13 | 1500 | 20 | 200 | 330 | 660 | 3700 | 1500 | 1200 | 4000 | 7.5 |

| DP-PBM 820 | 6 | 8 | 2000 | 205 | 185 | 308 | 615 | 4200 | 1500 | 1200 | 4000 | 7.5 |

| DP-PBM 1020 | 8 | 10 | 2000 | 220 | 200 | 330 | 660 | 4200 | 1500 | 1200 | 4500 | 7.5 |

| DP-PBM 1320 | 10 | 13 | 2000 | 235 | 215 | 353 | 705 | 4250 | 1500 | 1250 | 5100 | 7.5 |

| DP-PBM 1520 | 12 | 15 | 2000 | 265 | 245 | 398 | 795 | 4400 | 1520 | 1280 | 6250 | 11 |

| DP-PBM 1820 | 15 | 18 | 2000 | 290 | 270 | 435 | 870 | 4650 | 1750 | 1460 | 8500 | 15 |

| DP-PBM 2220 | 18 | 22 | 2000 | 320 | 290 | 480 | 960 | 4650 | 1750 | 1510 | 9000 | 18.5 |

| DP-PBM 2520 | 20 | 25 | 2000 | 345 | 315 | 518 | 1035 | 4800 | 1850 | 1600 | 11250 | 18.5 |

| DP-PBM 3020 | 25 | 30 | 2000 | 370 | 340 | 555 | 1110 | 5100 | 1920 | 1750 | 12500 | 22 |

| DP-PBM 3520 | 30 | 35 | 2000 | 410 | 380 | 615 | 1230 | 5250 | 1950 | 1850 | 14000 | 30 |

| DP-PBM 4020 | 35 | 40 | 2000 | 450 | 420 | 675 | 1350 | 5500 | 2000 | 1900 | 15300 | 30+7.5 |

| DP-PBM 5020 | 40 | 50 | 2000 | 470 | 450 | 705 | 1410 | 5600 | 2050 | 1950 | 17000 | 37+7.5 |

| DP-PBM 625 | 4 | 6 | 2500 | 220 | 200 | 330 | 660 | 4650 | 1400 | 1250 | 4750 | 5.5 |

| DP-PBM 825 | 6 | 8 | 2500 | 230 | 205 | 345 | 690 | 4650 | 1500 | 1250 | 5250 | 7.5 |

| DP-PBM 1025 | 8 | 10 | 2500 | 235 | 215 | 353 | 705 | 4750 | 1500 | 1250 | 6000 | 7.5 |

| DP-PBM 1325 | 10 | 13 | 2500 | 265 | 245 | 398 | 795 | 4900 | 1520 | 1280 | 6750 | 11 |

| DP-PBM 1525 | 12 | 15 | 2500 | 290 | 270 | 435 | 870 | 5150 | 1750 | 1460 | 9000 | 15 |

| DP-PBM 1825 | 15 | 18 | 2500 | 320 | 290 | 480 | 960 | 5150 | 1750 | 1510 | 10000 | 18.5 |

| DP-PBM 2225 | 18 | 22 | 2500 | 345 | 315 | 518 | 1035 | 5300 | 1850 | 1600 | 11250 | 18.5 |

| DP-PBM 2525 | 20 | 25 | 2500 | 370 | 340 | 555 | 1110 | 5600 | 1920 | 1750 | 14500 | 22 |

| DP-PBM 3025 | 25 | 30 | 2500 | 410 | 380 | 615 | 1230 | 5750 | 1950 | 1850 | 16000 | 30 |

| DP-PBM 3525 | 30 | 35 | 2500 | 450 | 420 | 675 | 1350 | 6000 | 2000 | 1900 | 18700 | 30+7.5 |

| DP-PBM 4025 | 35 | 40 | 2500 | 470 | 450 | 705 | 1410 | 6100 | 2050 | 1950 | 21000 | 37+7.5 |

| DP-PBM 5025 | 40 | 50 | 2500 | 490 | 470 | 980 | 1960 | 6200 | 2100 | 2000 | 23500 | 37+11 |

| DP-PBM 6025 | 50 | 60 | 2500 | 525 | 500 | 1100 | 2100 | 6300 | 2200 | 2100 | 27500 | 45+11 |

| DP-PBM 7025 | 60 | 70 | 2500 | 575 | 550 | 1265 | 2400 | 6400 | 2400 | 2300 | 31500 | 45+15 |

| DP-PBM 8025 | 70 | 80 | 2500 | 650 | 625 | 1500 | 2900 | 6500 | 2600 | 2500 | 36500 | 55+15 |

| DP-PBM 630 | 4 | 6 | 3000 | 220 | 200 | 330 | 660 | 5250 | 1500 | 1200 | 6000 | 7.5 |

| DP-PBM 830 | 6 | 8 | 3000 | 235 | 215 | 353 | 705 | 5300 | 1500 | 1250 | 6750 | 7.5 |

| DP-PBM 1030 | 8 | 10 | 3000 | 265 | 245 | 398 | 795 | 5450 | 1520 | 1280 | 8000 | 11 |

| DP-PBM 1330 | 10 | 13 | 3000 | 290 | 270 | 435 | 870 | 5700 | 1750 | 1460 | 10000 | 15 |

| DP-PBM 1530 | 12 | 15 | 3000 | 320 | 290 | 480 | 960 | 5700 | 1750 | 1510 | 11250 | 18.5 |

| DP-PBM 1830 | 15 | 18 | 3000 | 345 | 315 | 518 | 1035 | 5800 | 1850 | 1600 | 14000 | 18.5 |

| DP-PBM 2230 | 18 | 22 | 3000 | 370 | 340 | 555 | 1110 | 6150 | 1920 | 1750 | 16000 | 22 |

| DP-PBM 2530 | 20 | 25 | 3000 | 410 | 380 | 615 | 1230 | 6300 | 1950 | 1850 | 20000 | 30 |

| DP-PBM 3030 | 25 | 30 | 3000 | 450 | 420 | 675 | 1350 | 6550 | 2000 | 1900 | 21500 | 30+7.5 |

| DP-PBM 3530 | 30 | 35 | 3000 | 470 | 450 | 705 | 1410 | 6650 | 2050 | 1950 | 30000 | 37+7.5 |

| DP-PBM 4030 | 35 | 40 | 3000 | 490 | 470 | 980 | 1960 | 6750 | 2100 | 2000 | 32500 | 37+11 |

| DP-PBM 5030 | 40 | 50 | 3000 | 500 | 490 | 1000 | 2000 | 6950 | 2150 | 2050 | 36000 | 35+18.5 |

| DP-PBM 6030 | 50 | 60 | 3000 | 535 | 510 | 1125 | 2150 | 7000 | 2250 | 2250 | 39500 | 55+22 |

| DP-PBM 7030 | 60 | 70 | 3000 | 600 | 575 | 1320 | 2520 | 7200 | 2450 | 2400 | 43000 | 75+30 |

| DP-PBM 8030 | 70 | 80 | 3000 | 675 | 650 | 1575 | 3030 | 7400 | 2650 | 2600 | 48000 | 15 |

| DP-PBM 840 | 6 | 8 | 4000 | 290 | 270 | 435 | 870 | 6200 | 2100 | 1600 | 11800 | 18.5 |

| DP-PBM 1040 | 8 | 10 | 4000 | 320 | 300 | 480 | 960 | 6200 | 2100 | 1750 | 12750 | 18.5 |

| DP-PBM 1340 | 10 | 13 | 4000 | 250 | 325 | 525 | 1050 | 6200 | 2250 | 1850 | 13250 | 22 |

| DP-PBM 1540 | 12 | 15 | 4000 | 380 | 350 | 570 | 1140 | 6200 | 2250 | 1850 | 14000 | 30 |

| DP-PBM 1840 | 15 | 18 | 4000 | 420 | 390 | 630 | 1260 | 6600 | 2250 | 2100 | 16750 | 30+7.5 |

| DP-PBM 2240 | 18 | 22 | 4000 | 440 | 410 | 660 | 1320 | 7050 | 2300 | 2530 | 18750 | 37+7.5 |

| DP-PBM 2540 | 20 | 25 | 4000 | 460 | 430 | 690 | 1380 | 7150 | 2300 | 2530 | 21700 |