Features

- Guillotine Type Hydraulically Variable rake angle design.

- Better Cutting accuracy in thin sheets at lower rake angle with twist free cuts.

- The stable robust ultrasonically tester IS 2062 grade welded structure.

- Rigid box Type structure with inclined member for Ram & Table.

- Less power consumption.

- Hydraulic & Electrical Safety interlocks for overloading.

- Better Safety for operator and machine.

- Fast Production on smaller jobs.

- NC up-gradation available.

- Low noise & smooth operation gives higher efficiency of Operator.

- Higher cutting capacity at higher rake angle

Accessories

Standard Accessories – Hydraulic

- Main Drive Motor.

- Electric Control Panel.

- Operational Consol.

- Rake angle selection through selector switch

- Lever operated Blade clearance with calibration.

- Fine stroke adjustment rod with limit switch

- Front sheet support.

- Squaring arm with steel rule.

- Hardened Transfer bars mounted on table

- Hold down cylinders.

- Cutting area illuminated for clear view of blades.

- Four edge HCHCr Blade suitable to MS & SS.

- Manual Back Gauge.

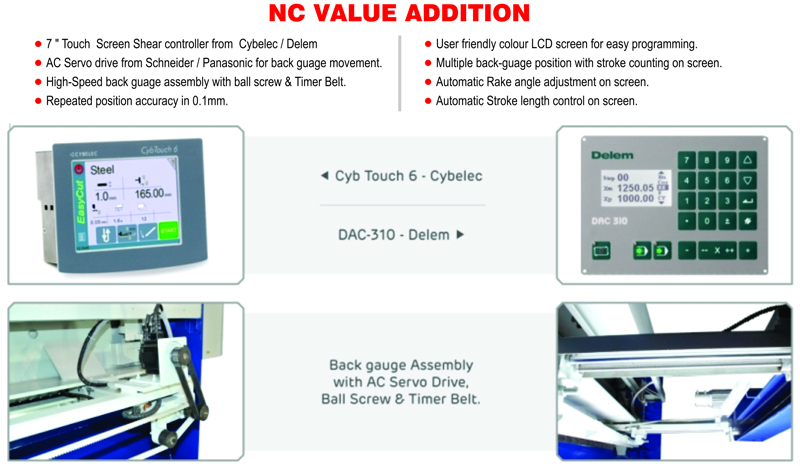

Standard Accessories – NC Control

- HMI with 2 Line 16 character LCD monochrome screen & numeric keypad

- Main Drive Motor.

- Electric Control Panel.

- Hardened Ground Ball screw & Linear motion bearings.

- Two-speed AC motor for back gauge drive.

- Rake angle selection through selector switch.

- Lever operated Blade clearance with calibration.

- Stroke adjustment through screen.

- Front sheet support.

- Squaring arm with steel rule.

- Hardened Transfer bars mounted on table.

- Hold down cylinders.

- Cutting area illuminated for clear view of blades.

- Four edge HCHCr Blade suitable to MS 8> SS.

Optional Accessories

(Hy. Shearing machine without NC)

- Motorized back gauge with DRO.

- Second squaring arm on other side.

- Front support with roller according to required length.

- Rear Sheet support.

- Timer belt drive for back gauge.

- Ball Transfer Table.

- Degree protector for angular cutting.

- Stroke counter.

- Design with throat depth.

- First fill of Hydraulic oil.

Specification

| Length Cutting | Shearing Capacity Nominal Rake Angle | Nominal Rake Angle | Rake Angle range | Rake Angle Stroke per min | No. of Hold downs | Holding Force | Power | Packing Dimension (LXWxH) in mm | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | in mm | Thickness in mm | in degree | in degree | Min. | Max. | in Kg. | in HP | |||||

| M.S. | S.S | ||||||||||||

| HFR215 | 1500 | 2 | 2 | 0.6 | 0.6 | 1° | 1° | 30 | 30 | _ | 3 | 2000x1000x1250 | |

| HFR 220 | 2000 | 2 | 2 | 0.6 | 0.6 | 1° | r | 25 | 25 | _ | _ | 3 | 2500x1250x1500 |

| HFR 225 | 2500 | 2 | 2 | 0.6 | 0.6 | 1° | r | 20 | 20 | 3 | 3000x1250x1850 | ||

| HFR 315 | 1500 | 3.15 | 4 | 2 | 3.15 | 1°15′ | 0.5-2° | 25 | 15 | 9 | 1500 | 3 | 2200x1250x1950 |

| HVR 320 | 2000 | 3.15 | 4 | 2 | 3.15 | ri5 | 0.5-3° | 20 | 11 | 11 | 2000 | 3 | 2700x1250x1950 |

| HVR 325 | 2500 | 3.15 | 4 | 2 | 3.15 | 1°15′ | 0.5-3° | 25 | 13 | 13 | 2300 | 5 | 3200x1250x2000 |

| HVR 330 | 3000 | 3.15 | 4 | 2 | 3.15 | 1°15′ | 0.5-3° | 21 | 9 | 16 | 2600 | 5 | 3700x1400x2100 |

| HVR 340 | 4000 | 3.15 | 4 | 2 | 3.15 | 1°15′ | 0.5-3° | 12 | 6 | 20 | 3200 | 7.5 | 4700x1500x2250 |

| HVR 415 | 1500 | 4 | 6 | 3 | 4 | 1°37′ | 0.5-3° | 25 | 13 | 8 | 4500 | 7.5 | 2250x1250x2050 |

| HVR 420 | 2000 | 4 | 6 | 3 | 4 | 1°37′ | 0.5-3° | 23 | 11 | 11 | 6200 | 7.5 | 2750x1250x2100 |

| HVR 425 | 2500 | 4 | 6 | 3 | 4 | 1°37′ | 0.5-3° | 21 | 8 | 13 | 8000 | 7.5 | 3300x1400x2250 |

| HVR 430 | 3000 | 4 | 6 | 3 | 4 | 1°37′ | 0.5-3° | 21 | 10 | 16 | 10000 | 10 | 3700x1500x2400 |

| HVR 440 | 4000 | 4 | 6 | 3 | 4 | 1°37′ | 0.5-3° | 15 | 6 | 20 | 12000 | 10 | 4700x1650x2600 |

| HVR 450 | 5000 | 4 | 6 | 3 | 4 | 1°37′ | 0.5-3° | 10 | 3 | 24 | 15000 | 10 | 5700x1700x2750 |

| HVR 460 | 6000 | 4 | 6 | 3 | 4 | 1°37′ | 0.5-3° | 10 | 3 | 28 | 15000 | 10 | 6700x1800x2850 |

| HVR 615 | 1500 | 6 | 8 | 4 | 6 | 1°45′ | 0.5-3° | 22 | 8 | 8 | 6500 | 10 | 2250x1300x2100 |

| HVR 620 | 2000 | 6 | 8 | 4 | 6 | 1°45′ | 0.5-3° | 20 | 7 | 11 | 6500 | 10 | 2750x1350x2150 |

| HVR 625 | 2500 | 6 | 8 | 4 | 6 | 1°45′ | 0.5-3° | 24 | 8 | 13 | 8500 | 15 | 3300x1500x2300 |

| HVR 630 | 3000 | 6 | 8 | 4 | 6 | 1°45′ | 0.5-3° | 22 | 6 | 16 | 10800 | 15 | 3800x1650x2500 |

| HVR 640 | 4000 | 6 | 8 | 4 | 6 | 1°45′ | 0.5-3° | 22 | 6 | 20 | 13600 | 20 | 4800x1700x2750 |

| HVR 650 | 5000 | 6 | 8 | 4 | 6 | 1°45′ | 0.5-3° | 18 | 4 | 24 | 16500 | 20 | 5700x1800x2850 |

| HVR 660 | 6000 | 6 | 8 | 4 | 6 | 1°45′ | 0.5-3° | 14 | 3 | 28 | 19500 | 20 | 6700x1900x2950 |

| HVR 815 | 1500 | 8 | 10 | 6 | 8 | 2° | 0.5-3° | 15 | 8 | 8 | 10500 | 10 | 2250x1350x2100 |

| HVR 820 | 2000 | 8 | 10 | 6 | 8 | 2° | 0.5-3° | 18 | 8 | 11 | 12000 | 15 | 2750x1450x2250 |

| HVR 825 | 2500 | 8 | 10 | 6 | 8 | 2° | 0.5-3° | 20 | 8 | 13 | 16500 | 20 | 3300x1650x2450 |

| HVR 830 | 3000 | 8 | 10 | 6 | 8 | 2° | 0.5-3° | 18 | 6 | 16 | 18500 | 20 | 3800x1800x2600 |

| HVR 840 | 4000 | 8 | 10 | 6 | 8 | 2° | 0.5-3° | 16 | 4 | 20 | 23000 | 20 | 4800x1850x2800 |

| HVR 850 | 5000 | 8 | 10 | 6 | 8 | 2° | 0.5-3° | 12 | 3 | 24 | 27000 | 25 | 5750x1950x2900 |

| HVR 860 | 6000 | 8 | 10 | 6 | 8 | 2° | 0.5-3° | 8 | 2 | 28 | 31000 | 25 | 6750x2100x3100 |

| HVR 1015 | 1500 | 10 | 13 | 8 | 10 | 2° | 0.5-3° | 14 | 6 | 8 | 10500 | 10 | 2250x1350x2200 |

| HVR 1020 | 2000 | 10 | 13 | 8 | 10 | 2° | 0.5-3° | 18 | 8 | 11 | 13000 | 15 | 2750x1500x2300 |

| HVR 1025 | 2500 | 10 | 13 | 8 | 10 | 2° | 0.5-3° | 15 | 8 | 13 | 17500 | 20 | 3300x1650x2500 |

| HVR 1030 | 3000 | 10 | 13 | 8 | 10 | 2° | 0.5-3° | 12 | 6 | 16 | 20000 | 20 | 3800x1850x2750 |

| HVR 1040 | 4000 | 10 | 13 | 8 | 10 | 2° | 0.5-3° | 13 | 6 | 20 | 25000 | 25 | 4800x1950x2850 |

| HVR 1050 | 5000 | 10 | 13 | 10 | 2° | 0.5-3° | 10 | 5 | 24 | 30000 | 30 | 5750x2050x3000 | |

| HVR 1060 | 6000 | 10 | 13 | 8 | 10 | 2° | 0.5-3° | 8 | 3 | 28 | 35000 | 30 | 6750x2200x3300 |

| HVR 1320 | 2000 | 13 | 16 | 10 | 13 | 2° | 1-3° | 15 | 8 | 11 | 16000 | 25 | 2850x1800x2600 |

| HVR 1325 | 2500 | 13 | 16 | 10 | 13 | 2° | 1-3° | 13 | 6 | 13 | 20000 | 25 | 3350x1900x2750 |

| HVR 1330 | 3000 | 13 | 16 | 10 | 13 | 2° | 1-3° | 11 | 6 | 16 | 25000 | 25 | 3800x1950x2850 |

| HVR 1340 | 4000 | 13 | 16 | 10 | 13 | 2° | 1-3° | 9 | 4 | 20 | 30000 | 30 | 4800x2000x2950 |

| HVR 1350 | 5000 | 13 | 16 | 10 | 13 | 2° | 1-3° | 9 | 4 | 24 | 35000 | 40 | 5750x2150x3150 |

| HVR 1360 | 6000 | 13 | 16 | 10 | 13 | 2° | 1-3° | 7 | 3 | 28 | 40000 | 40 | 6750x2300x3500 |

| HVR 1620 | 2000 | 16 | 20 | 13 | 16 | 2° | 1-3° | 18 | 6 | 11 | 20000 | 30 | 3000x1900x2800 |

| HVR 1625 | 2500 | 16 | 20 | 13 | 16 | 2° | 1-3° | 15 | 5 | 13 | 25000 | 30 | 3500x2000x2900 |

| HVR 1630 | 3000 | 16 | 20 | 13 | 16 | 2° | 1-3° | 12 | 5 | 16 | 28000 | 30 | 4000x2000x3000 |

| HVR 1640 | 4000 | 16 | 20 | 13 | 16 | 2° | 1-3° | 7 | 3 | 20 | 33000 | 30 | 4800x2050x3100 |

| HVR 1650 | 5000 | 16 | 20 | 13 | 16 | 2° | 1-3° | 7 | 3 | 24 | 38000 | 40 | 5750x2250x3300 |

| HVR 1660 | 6000 | 16 | 20 | 13 | 16 | 2° | 1-3° | 5 | 2 | 28 | 43000 | 40 | 6750x2350x3700 |

| HVR 2025 | 2500 | 20 | 25 | 16 | 20 | 2° | 1-3° | 12 | 5 | 13 | 28000 | 40 | 3500x2000x3000 |

| HVR 2030 | 3000 | 20 | 25 | 16 | 20 | 2° | 1-3° | 11 | 5 | 16 | 35000 | 40 | 4000x2100x3200 |

| HVR 2040 | 4000 | 20 | 25 | 16 | 20 | 2° | 1-3° | 9 | 4 | 20 | 40000 | 50 | 4800x2200x3300 |

| HVR 2050 | 5000 | 20 | 25 | 16 | 20 | 2° | 1-3° | 8 | 3 | 24 | 45000 | 60 | 5800x2350x3500 |

| HVR 2060 | 6000 | 20 | 25 | 16 | 20 | 2° | 1-3° | 5 | 2 | 28 | 50000 | 60 | 6800x2450x4100 |

| HVR 2525 | 2500 | 25 | 30 | 20 | 24 | 2° | 1-3° | 10 | 4 | 13 | 36000 | 60 | 3400x2250x3300 |

| HVR 2530 | 3000 | 25 | 30 | 20 | 24 | 2° | 1-3° | 8 | 4 | 16 | 45000 | 60 | 4000x2300x3300 |

| HVR 2540 | 4000 | 25 | 30 | 20 | 24 | 2° | 1-3° | 7 | 4 | 20 | 50000 | 75 | 5000x2300x3500 |

| HVR 2550 | 5000 | 25 | 30 | 20 | 24 | 2° | 1-3° | 5 | 2 | 24 | 55000 | 75 | 6000x2450x3700 |

| HVR 2560 | 6000 | 25 | 30 | 20 | 24 | 2° | 1-3° | 3 | 1 | 28 | 60000 | 75 | 7000x2600x4300 |

Parts

Diagram